South Africa

South Africa

Angola

Angola

Algeria

Algeria

Botswana

Botswana

Cameroon

Cameroon

Republic of the Congo

Republic of the Congo

Egypt

Egypt

Ethiopia

Ethiopia

Guinea

Guinea

Ghana

Ghana

Kenya

Kenya

Liberia

Liberia

Libya

Libya

Morocco

Morocco

Malawi

Malawi

Mozambique

Mozambique

Namibia

Namibia

Nigeria

Nigeria

Rwanda

Rwanda

Senegal

Senegal

Sudan

Sudan

Tanzania

Tanzania

Tunisia

Tunisia

Uganda

Uganda

Zambia

Zambia

Zimbabwe

Zimbabwe

Europe

Europe

USA

USA

Lesotho

Lesotho

United Arab Emirates

United Arab Emirates

Saudi Arabia

Saudi Arabia

Qatar

Qatar

Kuwait

Kuwait

Bahrain

Bahrain

Brazil

Brazil

Spain

Spain

Jordan

Jordan

France

France

Canada

Canada

Cyprus

Cyprus

Mauritius

Mauritius

Côte d'Ivoire

Côte d'Ivoire

Mali

Mali

Burkina Faso

Burkina Faso

Togo

Togo

Benin

Benin

Mexico

Mexico

Central African Republic

Central African Republic

Eswatini

Eswatini

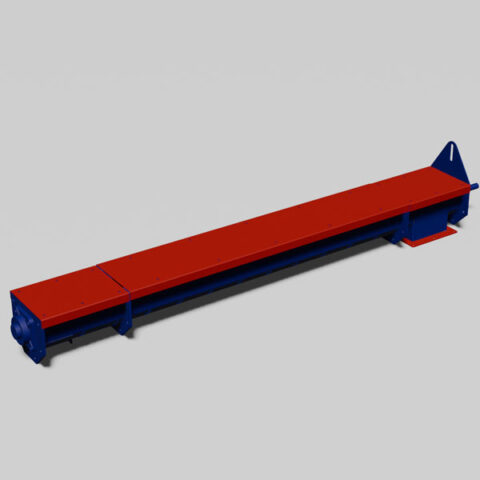

Screw conveyors Trough Augers Sizes 165mm x 2.1m | ABC Hansen Africa

Price range

ZAR 41,235.02 - ZAR 84,980.40

Including VAT

Description

Screw conveyors have been used since ancient times in the conveyance of products – with the first iteration being the Archimedes screw, that was used for pumping water for irrigation. We’ve

come a long way since then in other things – but on screw conveyors – we’re still using Archimedes’ principles, with very little changes. Trough augers are different from tube augers – as the spiral runs in a U-shaped trough, with removable lids as opposed to running in a round tube.These augers are typically used in horizontal and low incline applications, and are available with enclosed, or mesh covered top lids.

The advantages of a trough auger are that the body of the conveyor is easily accessible for maintenance of carrier bearings, cleaning, the construction allows for longer conveyor lengths than on tube conveyors.

Trough conveyors are commonly used in silo loading and unloading and in high maintenance and high hygiene applications. Trough auger are usually built in bolt together segments for easy transportation and assembly on site

Trough conveyors are able to be used in inclinations of up to 45º, but we suggest maximum 15º inclines

Lengths noted here are standard lengths, but custom lengths up to 18m can be manufactured on special order.

ABC Hansen Africa is a South African, family-owned company affiliated with ABC Hansen A/S of Denmark and part of an international group with operations in Europe, Africa, and Asia. The group includes well-known brands like Engsko, Hippo Mills, and Scanwood Solutions, with a presence in countries such as Namibia, Zambia, Kenya, Ghana, and India.

Operating from a 5,000m² facility in Pretoria, ABC Hansen designs, manufactures, imports, and exports agricultural and food processing equipment. Their expertise spans the entire grain value chain, with a strong focus on grain storage systems, milling, oilseed processing, and turnkey plant solutions.

The company not only builds machinery but also operates and supports systems locally and abroad, offering full engineering, maintenance, and repair services. Known for innovations like the Hippo Hammer Mill and compact milling systems, ABC Hansen is committed to quality, reliability, and ongoing research and development.

Contact us today!

Location:

216 Propshaft Rd, Pretoria, South Africa

Follow us on:

Click HERE to visit our website.